Prototypes – Precision Machining

Smithstown UK offer our customers a complete design and manufacturing solution for the development of prototype products. Our core business through our 40 year history has been small batch or custom one-off part manufacture. As such, we are set up to develop prototype parts.

Smithstown offer the following capabilities:

- Project Management expertise – each member of our Project Engineering and Customer Service department (PECS dept) has over 20 years experience in the tool making industry. Such expertise and experience is an invaluable

asset in the early stages of your prototype product.

asset in the early stages of your prototype product. - Prototype and Tooling Design – technical expertise and leadership, guidance on how to design for manufacturing. CAD software is used to simulate your product before manufacturing (Unigraphics NX, solidworks systems used).

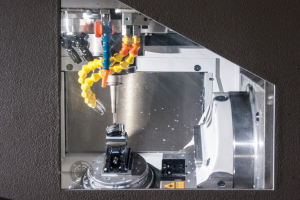

- World Class Manufacturing Capabilities– we have an extensive range of manufacturing capabilities, (see from the main menu), all available onsite and all available to scale up from a prototype run to a full production run.

- Quality Systems- certified ISO9001 (Quality), ISO13485 (Medical devices), ISO14001 (Environmental Standard). We have trained Six Sigma black belts and implement Six Sigma and Lean Principles in all of our production processes. We have significant inspection equipment capabilities, CMMs, 3D scanning heads Smartscope Vision Systems, surface finish testing.

- Product Validation Methodologies – PPAP, Process Maps, Risk Analysis, First Article Inspections, Process Capabilities, Machine IQ and OQs, Cpk and Ppk, Gage R&R.

- Supply Chain Management – whether we manufacture your prototype in-house or offer our expertise in working with supply chain partners in the far east, Smithstown have the network infrastructure in place, and can simplify your supply chain into a single point of contact.

Smithstown have 40 years experience in precision engineering. We have the expertise to take your product from its concept phase through design into a working prototype, and ultimately into a fully validated production process. We strive to turn new customers into return customers. We do this by building close relationships with out customer and by guaranteeing quality in all our work.