Promoting Careers in Engineering

Once again we are delighted to be taking part in the annual Limerick for Engineering Showcase this year and playing our part in promoting all that's great about a career in engineering. As an indigenous engineering firm in the mid-west, we are proud to be members of the Limerick for Engineering group - an industry led initiative which has support of the education and training providers in the region. The primary goal of Limerick for Engineering is to the increase the quality and quantity of engineering talent (apprentice, technicians and engineers) available in the region. Event details: Date: Thursday March 7th, 2019 [...]

Lean Project Builds Relationships, Improves Quality

After taking a Lean Six Sigma approach to solving a particular quality and yield issue, Smithstown Light Engineering’s lean journey is now focused on continuous improvement and creating a culture that engages employees while enhancing performance. In this article we look at how the journey began and the benefits that ensued. Smithstown’s history is in the manufacturer of high quality and precision custom-made injection moulds and low volume custom tooling. The company has expanded over the years and now specialises in the provision of precision engineering solutions to the top medical device and orthopedic companies in the world. This [...]

Six Staff Celebrate 30 Years at Smithstown

Six staff celebrated their 30th anniversary working for Smithstown Light Engineering recently. Pat King, Corofin, Christy Farrell, Kilmurray, Tom Dwyer, Shannon, Kieran O’Reilly, Sixmilebridge, Mike Foley, Cratloe and Pat Sheehy, Hospital were recognised for their long service and commitment to our company at a special celebratory event. Gerard King, managing director at Smithstown Light Engineering, said, “We are delighted to recognise our colleagues who have been with us for 30 years and thank them for their loyalty and commitment over the years. Their long service is testimony of their ability to adapt and learn as our company has evolved [...]

Investment in Citizen L12 CNC Sliding Head Lathe with LFV technology

The delivery of 4 x Citizen L12 CNC Sliding Head Lathes with LFV technology (coupled with IEMCA bar feeders) marks another exciting phase in our ongoing expansion and continuous investment in our capabilities. The L12 is the perfect solution for small diameter work with switchable guide bush and 15,000 rpm spindle and its LFV technology allows us to meet customer demand for effective machining of difficult-to-cut materials. Citizen's L series represents the new ‘standard’ in automatic lathes for function and performance. At Smithstown Light Engineering we're all about Precision.... in everything we do. For more information, please contact us on +353 [...]

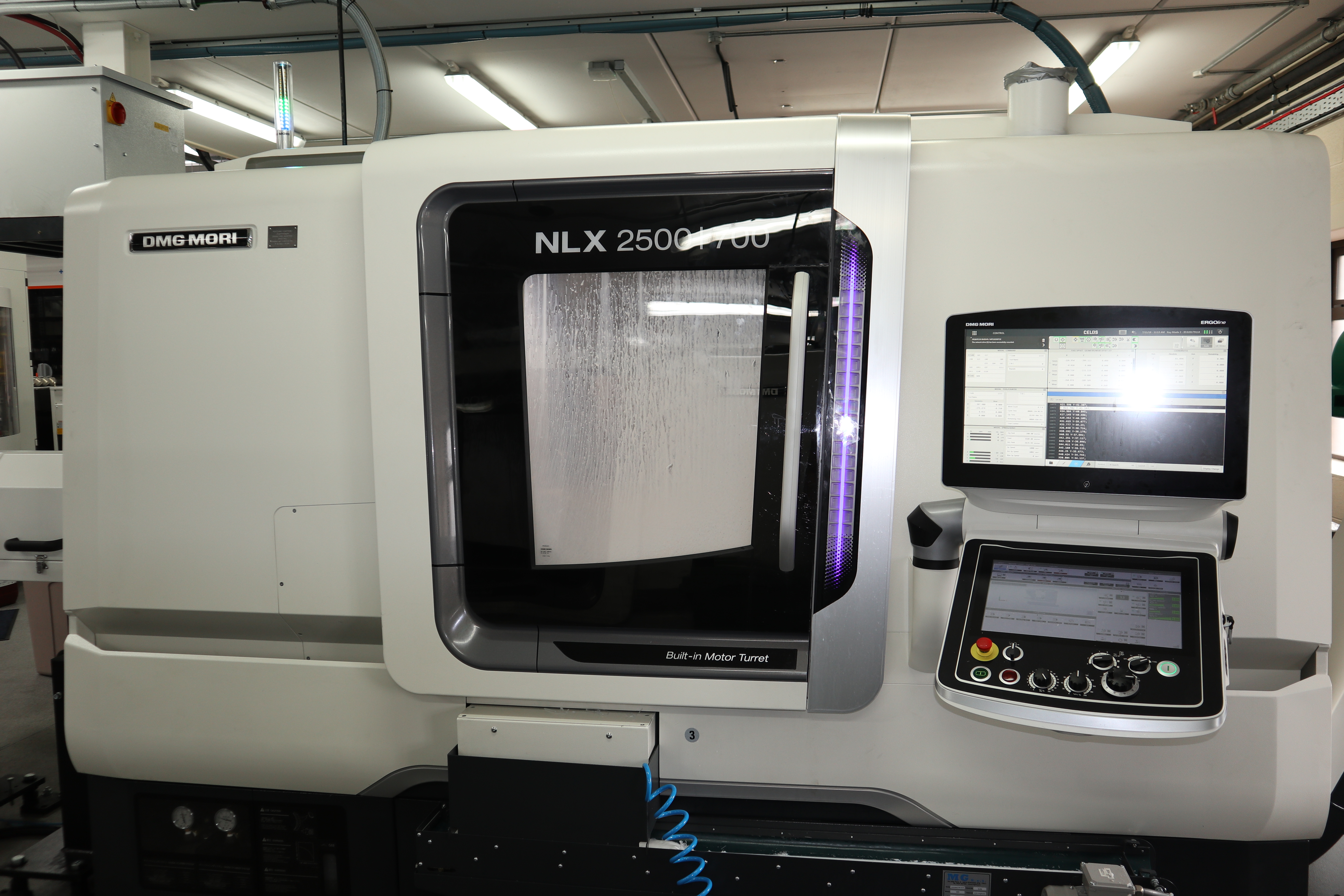

Another 2 x Mori Seiki NLX2500/700 Mill/Turn machines added

Smithstown Light Engineering has just added our second and third Mori Seiki NLX2500 to our production floor. All our mill/turn machines are equipped with automatic Multifeed bar loaders. That's another addition to our milling and turning department in the last few months.

New – Mori Seiki NLX2500/700 and NTX2000

In the last few months Smithstown Light Engineering Ltd. have installed 2 multi axis machines: Mori Seiki NLX2500/700 and second NTX2000. Thanks to this investments we could increase our efficiency while keeping our highest market standards in quality and precision. Contact SLE for more information

Expansion plans for Smithstown Light Engineering

Due to continued growth, Smithstown Light Engineering Ltd. (SLE) have recently completed an investment in a 10,000 square mtr. facility neighbouring our head office in Shannon, Co. Clare. With this extra floor capacity secured, SLE plan to invest a further €4m over the next three years on machinery at this facility and plan to create up to 25 jobs across several of our production departments. SLE's expansion plans have been driven by strong growth in our business particularly in our contract manufacturing sector, our medical devices sector and our wax mould tooling sector. Our aim in expanding our production [...]

SSL Implementation for SLE

Smithstown Light Engineering (SLE) is proud to announce the implementation of SSL on all our websites. SSL is a communication security protocol that is in widespread use for website communication over the internet. In other words, this technology ensures more secure link between our clients' browser and our website. We used LetsEncrypt Technology on both our our sites. The installation was carried out by ABCDigital.ie. ABC Digital is the parent company of the leading SEO Ireland company CreatorSEO.com. Let’s Encrypt is a free, automated, and open Certificate Authority that empowers site owners to implement SSL without having to spend exorbitant amounts on [...]

New – Mikron 5 Axis Milling Production Cell

Two months ago Smithstown Light Engineering Ltd. have installed third Mikron 5 Axis Production cell, each cell comprised of 2 Mikron HSM 400U LP workcenters loaded robotically by a System 3R pallet loader. With a capacity of 96 pallets, the robotic pallet loader ensures that both machines are kept running 24/7. Thanks to that production cell we could increase our efficiency while keeping our highest market standards in quality and precision. Please see the video of this machine working below:

New – 2x Jung J630-D surface grinders

Smithstown Light Engineering continue to invest in high end technology. This month we have added 2x Jung J630-D CNC surface grinders to our equipment list. The key features are: Manual/hydraulic longitudinal stroke : 630 [mm] Transversal stroke : 275 [mm] Vertical stroke : 360 [mm] Table dimensions : 600 x 250 [mm] Max. load on table : 130 [kg] Grinding wheel speed : 800 - 4.200 [Rpm] Grinding wheel motor power : 10 [kW] Grinding wheel dimensions : 300 x 30 x 76,2 [mm] Contact us for more information