High capacity for high precision surface grinding

At Smithstown UK, we offer a high precision, CNC Surface Grinding services to companies throughout the UK. We provide precision ground parts to a range of customers in a range of industries such as Medical Devices, Aerospace, and Automotive. We can manufacture using a wide range to materials from tool steels or medical stainless steels to aluminiums or other exotic steels or hardened steels.

We have invested heavily in our surface grinding capabilities and have 7 Jung surface grinders (5 x J630D, 1 x Vario , 1 x JF520), we also have 5 Jones and Shipman surface grinders ((1 x Dominator, 2 x CNC & 2 x manual) and an Okomoto completes our grinding resources. Our skilled operators and wide range of resources ensure that we can precision grind a wide range of steels to within micron tolerances.

Smithstown UK Surface Grinding Services include our CNC Jung J630-D grinders

– offering a wide range of capabilities such as

- CNC Surface Profile range- 600 x 300 x 300mm

- Reciprocation type surface and profile grinding

- Creep feed grinding

- Contour path grinding in XY and YZ planes

- Fully CNC controlled continious/ simultaneous wheel dressing.

- PA-37 CNC controlled 4 Axis dresser which can be configured with a 5 tool diamond tool holder or with a rotating diamond wheel

- Continuous automatic dressing (dressing and machining simultaneously) using the PA-37 ensures high precision and

- High productivity for our customers by reducing retraction cycles from the work piece

High Precision, High Quality Surface Grinding

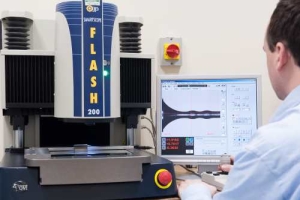

As quality is at the core of everything we do at Smithstown UK, we have made a big investment in quality systems. This allows us to control the method of manufacture and ensure accuracy of measurement. We have integrated two Smartscope Flash CNC optical visions systems direct into our grinding department where our operators can check their work under 300x magnification.

The Smartscope can be programmed and these programs can be controlled if used as part of a validated manufacturing process. This ensures accuracy and repeatability by automating the inspection process and reducing the opportunity for operator error

Find out more about our high precision grinding services: