Wire Erosion Services – Over 1100 hours wire EDM machining capacity every week

Smithstown UK have have offered wire erosion services for over 40 years.

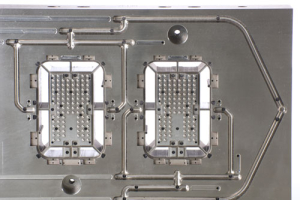

Our team of skilled operators keep our 3 Agie charmilles wire EDM and 3 Makino (2 x U6and U3) machines operating 24 hours a day and 7 days a week.

We routinely cut with wire as small as 0.1mm for intricate jobs and we also cut with wire as large as 0.3mm for quicker cuts. We can cut to tolerances of .0025mm with a machined surface finish of 6µm if necessary. All our WireEDM machines are fully CNC with autothreading capable. Smithstown UK can machine any conductive materials.

Dedicated wire erosion programming team and Clean Cut

– each job is programmed offline using PEPS EDM software

We have a dedicated Wire EDM programming department who program each job offline using latest Visi software. We also use the latest in clean cut technology on our machines. Clean cut technology enhances cutting times and reduces pollution formation on the component surface. Wire EDM is particularly efficient at cutting very intricate or delicate, thin walled parts which may be prone to warping when being machined using traditional methods. Part Hardness is not of concern as wire EDM is effectively a non-contact machining process which uses a spark to remove material rather than a cutting edge. We can also cut tapered holes up to 40° included angle.

Our extensive wire erosion services (wire EDM) and machining capabilities make us a key subcontract partner for many industries. For exceptionally high quality of accurately machined components and finished assembly parts, please contact us today.