Due to continued growth, Smithstown Light Engineering Ltd. (SLE) have recently completed an investment in a 10,000 square mtr. facility neighbouring our head office in Shannon, Co. Clare.

With this extra floor capacity secured, SLE plan to invest a further €4m over the next three years on machinery at this facility and plan to create up to 25 jobs across several of our production departments. SLE’s expansion plans have been driven by strong growth in our business particularly in our contract manufacturing sector, our medical devices sector and our wax mould tooling sector. Our aim in expanding our production capacity is further broaden our manufacturing capacities, while also offering tighter lead times to our customers.

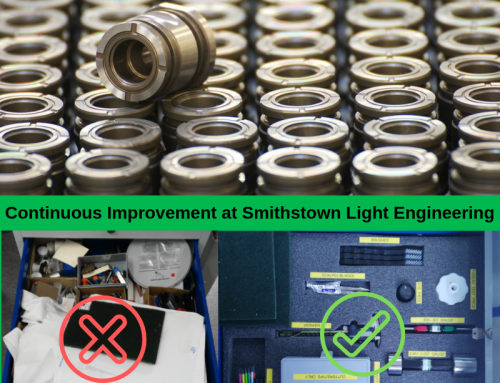

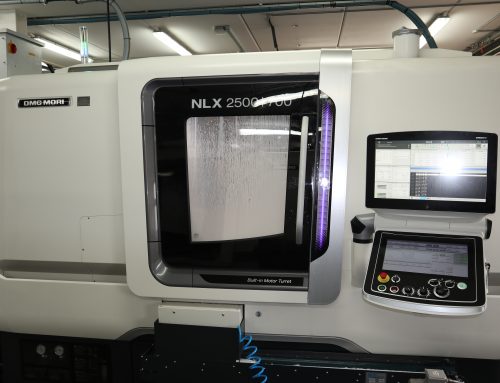

SLE’s policy of investing in cutting edge manufacturing technology and machinery, has driven investment of over €5m over the last 5 years and has seen delivery of several Mori Seiki multi axis machining centres, Mikron production cells, Jung CNC grinders, Amada fibre laser cutters, as well as other supporting and finishing processes such as passivation, electro + vapor polishing among others. SLE@s focus on increasing automation has allowed greater cost effectiveness and lower labour overheads for our customers.

Smithstown Light Engineering Ltd. is an Irish owned precision engineering company founded is 1974. Over the last 40 years manufacturing in Shannon, Smithstown have earned a reputation for premium quality and first class customer service, and have served customers such as Stryker, DePuy Synthes, Boston Scientific, BD, Cook Medical, Red Bull F1 racing among many others in that time.