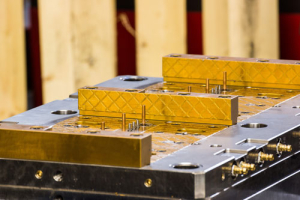

Our Tool Assembly Team: skilled toolmakers ensuring quality in every tool built

We have a very experienced tool assembly team. Our toolmakers assemble and debug every tool manufactured in Smithstown. We test run any plastic or wax injection mould tools we build any injection moulding products.

We invite our customers onsite to collaborate in our mould sign-off process. We also, can offer F.A.T and tool validation when required.

40 years experience in Injection Moulding product making

Over the last 40 years Smithstown, our tool assembly team have manufactured and assembled hundreds of technically challenging tools for customers in industries such as:

- Medical Devices (check valves, syringes, IV drip components, stent delivery systems, test tube well plates, various medical fasteners and connectors)

- Medical – Blood Filtration, (manufactured dozens of adult and paediatric blood filtration moulds)

- Automotive (cable loom connectors, airbag release system components. dashboard components)

- Aerospace ( cabling connectors)

- Defense (battery components)

- Household Appliances (water filtration, dryer filters, household bottles and bottle tops )

- Packaging (tooling for high volume manufacturing of blister packs)

- Consumer goods (soap piston dispensers, bottles, fasteners, bottle tops)

- Electronics (moulded connectors, mobile phone components)

Contact Us to find out about our tool assembly and injection moulding product capabilities.

Mould Maintenance & Refurbishments

Through the skilled toolmakers in the Smithstown UK tool assembly department we are able to offer our customers the facility to outsource their mould maintenance to a team of toolmakers who have a world class manufacturing facility to call on when parts need to be refurbished or remade. This approach enables us to liaise direct with our customers maintenance managers to manage and minimise production downtime.